In the past few weeks, dozens of wildfires have ravaged the western United States continuing a disturbing and increasing trend. The causes of many of the fires are still being investigated, but if the El Dorado fire is any indication, we can anticipate that the majority won’t be attributed to natural occurrences. According to the U.S. Department of the Interior, only 10% of wildfires in the U.S. are sparked by natural occurrences such as lightning. In fact, most are started by human activity and equipment, including incidents related to transmission lines and electrical equipment. Sparks from damaged power lines or wind-toppled live wires can quickly ignite dry vegetation, as was the case for the 2018 Camp fire in California. Ignited when a live wire broke off a 99-year old electric tower, the fire caused 85 deaths and burned more than 18,000 homes, businesses, and other structures. It remains, to date, the single most destructive fire in the state’s history. Though electricity-caused fires represent a fraction of total accidents, wildfire safety investigations have found that these types of fires cause a disproportionately high number of the most damaging incidents. The same hot, dry, windy conditions that make it more likely for electrical infrastructure to spark also create dangerous conditions for fires to spread quickly out of control. Thus, electricity-caused fires usually ignite when the consequences are most deadly.

Safety commissions have touted a number of tech-focused solutions such as automated inspections, the use of LiDAR and cameras to map vegetation, weather station monitoring, and data analytics as ways to combat powerline-induced wildfires. These strategies attempt to identify high-risk areas for maintenance and vegetation pruning, and in more modernized grids, preemptively shut-off power to sections of the grid during extreme weather events. Among the challenges with some of these monitoring solutions, primarily high-resolution tech like LiDAR and remote cameras, is that they are costly and require maintenance, presenting a barrier for utility companies that cannot legally pass extraordinary or unbudgeted costs to consumers. Additionally, equipment that is expensive or complex to install would be impractical for covering hundreds of thousands of miles of distribution lines, often in remote areas. Currently, the default solution for many parts of California’s grid is rolling brown-outs—cutting power to large areas covering millions of homes, for up to days at a time during peak fire conditions. This is a blunt, last-resort tool that itself causes economic and human harm, especially to those reliant on electricity for medical needs and communicating impending fire danger. Monitoring and data collection on power lines present an opportunity for the application of multiple existing and emerging technologies, some of which are already common in other industries. Picture a network of reliable, robust sensors capable of being installed alongside current infrastructure, able to identify areas of high localized fire danger and even detect events down to a specific line, all while sending signals back to the main distribution and control hubs in near-real time. Technologies like edge AI, inductive energy harvesting, and secure long-range wireless mesh networks could make a system like this a reality, painting a more detailed picture for utilities of the current status of their electrical infrastructure.

A frequent buzzword in the consumer tech world, “edge AI” involves predictive algorithms tuned on training data, like those that enable your cell phone to recognize whether you’re walking, running, or speaking to your virtual assistant. The “edge” component involves implementing these locally on hardware that does not have to communicate with a central server or cloud, opening the door for algorithms to be applied with hardware that is off-the-grid, or must save its power-hungry wireless module for critical communications. Running AI algorithms locally also minimizes the latency between event and detection by eliminating the round trip communications time. In the context of power line monitoring, an edge processing sensor could take any number of inputs in the field such as accelerometer data, temperature, or even line current readings to, for example, determine exactly where and when a tree has struck a power line. Though this capability might also be provided by simple threshold detection, a well-trained AI algorithm would additionally be able to distinguish between more nuanced events, such as whether a cable is swaying due to wind or because a tree branch has impacted, allowing for higher fidelity data with simple sensors. The key to well-performing machine-learning approaches is training with enough good data – by adding inputs from affordable embedded sensors mounted on power lines to currently available weather station data, a predictive model for this application could be built. These types of machine learning approaches are already being used to tackle problems such as maintenance of critical generator components at power stations, where multiple complex variables affect simple outcomes.

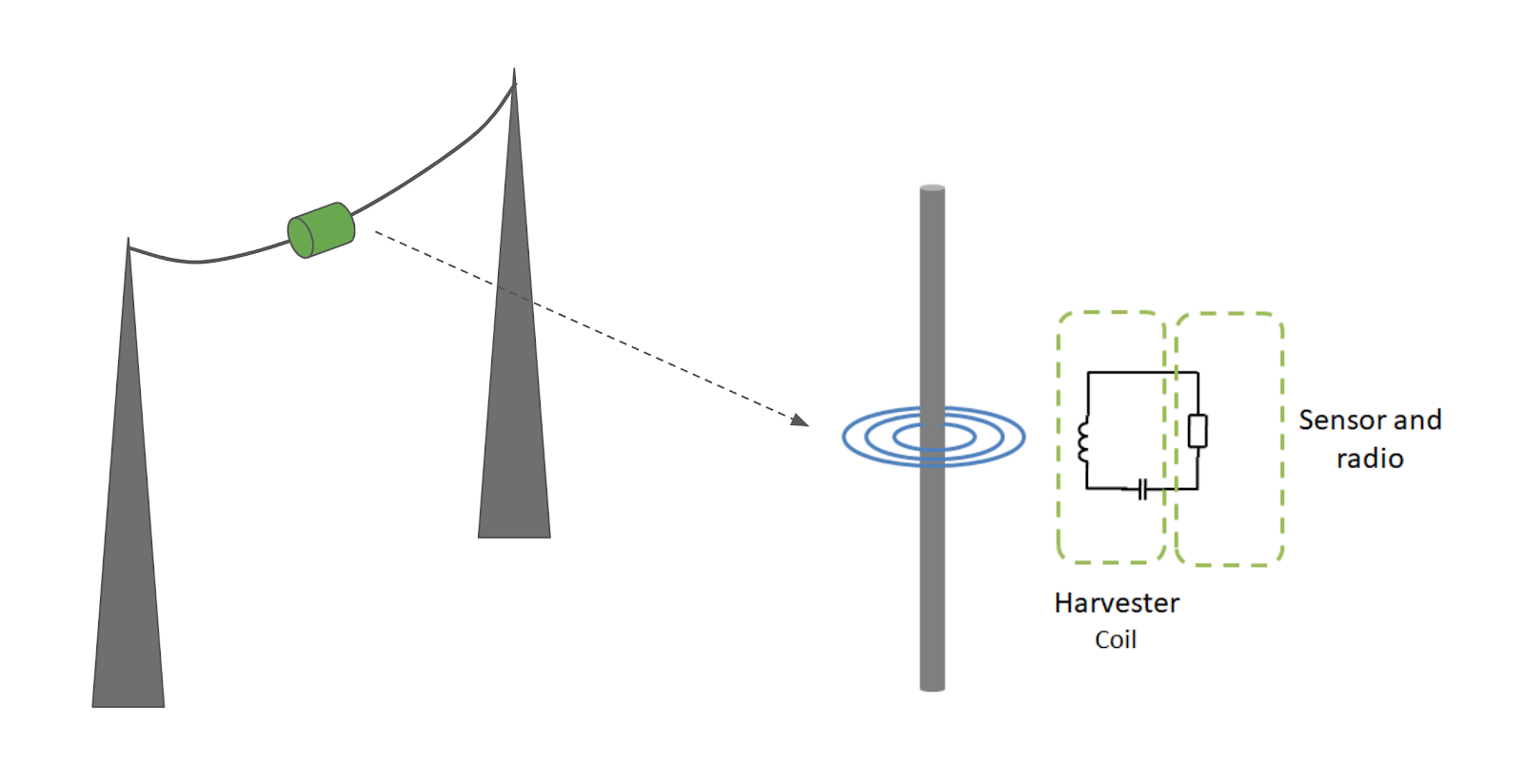

The primary maintenance cost for most remote monitoring systems is battery replacement for each module, so any smart system used needs to be self-powered in order to be practical. Monitoring sensors and communications systems have to be designed to be not only reliable, but also energy efficient to be scalable and economically viable across far-flung power lines. While it may seem that power lines carrying electricity would be the ideal power source to tap into, it is actually quite the technical challenge to convert the high-voltage, low amperage AC carried by a line into usable power for DC electronics, in a small and non-obtrusive package. Particularly for distribution lines, ranges of line current can vary in both magnitude and polarity from less than an Amp to hundreds of Amps due to varying downstream energy demand and grid location, making it a unique challenge to design electronics capable of performing well across this input range.

The most viable form of energy harvesting for this application is based on the physical principle of inductive coupling, where the changing magnetic field generated by power lines can be used to induce a voltage on a nearby coil. A well-designed coil, optimized for energy harvesting and mounted on a power line is capable of providing enough power to run a few sensors, a radio, and support electronics with a life-span in years. Powered by such an inductive harvester, a remote sensor would only require a small battery for back-up power, and would likely only need replacement in the event of damage from wind or fire.

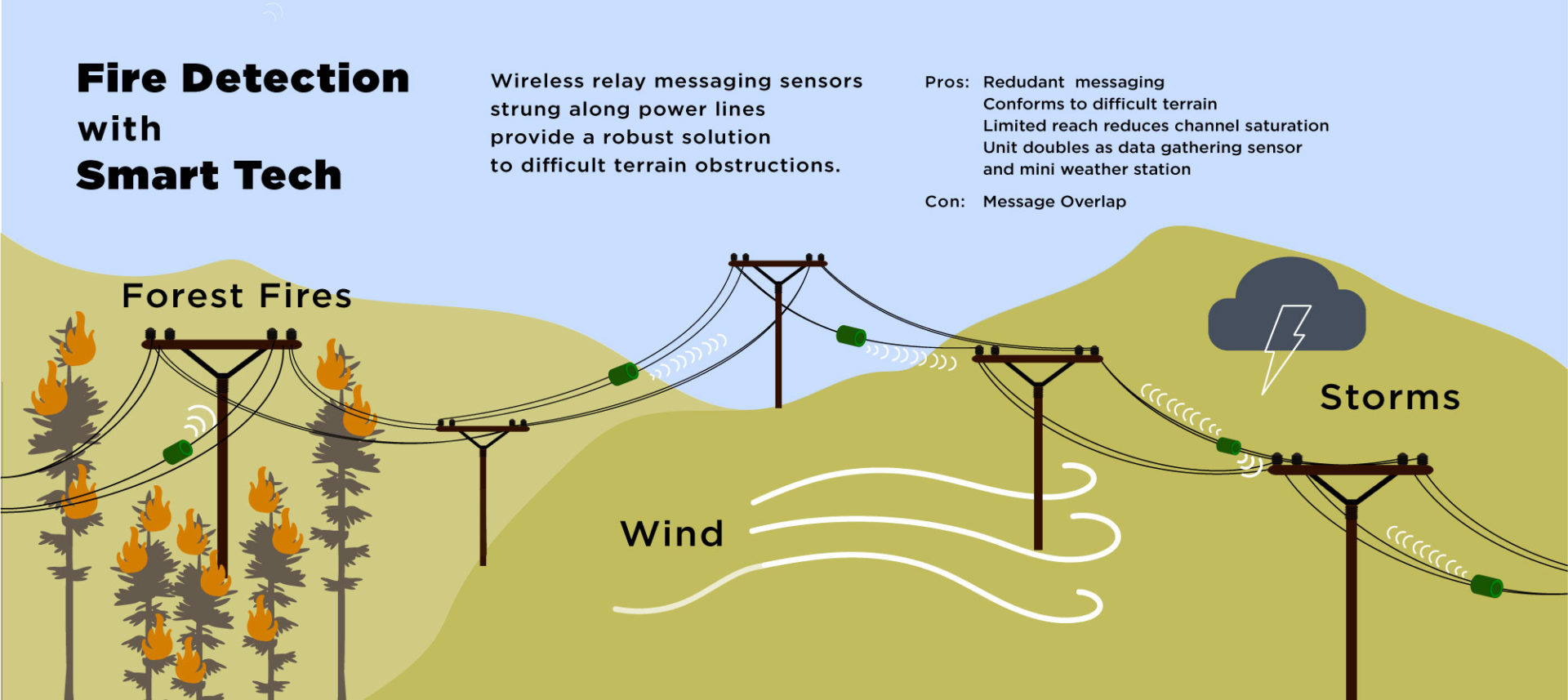

Even if a monitoring system is reliable and low-cost enough to be deployed widely across a grid system, it still must be capable of relaying information back to the utility’s data center. In remote areas carrying transmission lines susceptible to fires, cellular data may be limited or non-existent, rugged terrain can provide challenges for traditional radio technology, and satellite communications are expensive. Additionally, when every second matters in responding to a potential wildfire event, reducing data latency creates an even more challenging communications problem. A type of infrastructure commonly known as a wireless mesh network can solve many of these challenges. In a mesh network, individual nodes send information to adjacent nodes, allowing a message to be routed over long distances and rugged terrain using multiple “hops.”

Mesh networks are used in diverse applications ranging from home WiFi coverage to connecting school laptops to the Internet in regions with few access points. This type of network is very reliable and resilient, even to the loss of single nodes in a stable network with routing points that don’t move much—an ideal fit for electrical infrastructure. Enabling remote sensors on a segment of transmission line to relay information in this way becomes a well-defined problem for a wireless network designer, in that the complexities of frequency, protocol, energy usage, and number of nodes required can be based on the typical distance between the modules. A well-designed mesh network would relay critical information to a utility’s control center in real-time, allowing smarter automated line de-energizing with better, timelier data. This technology could also enable a greater number of lower-cost weather stations, allowing real-time understanding of micro-climates during peak fire seasons and more granularity in point forecasts.

Though it is exciting to think about the applications of flashy new technologies, it’s important as product designers to think about what real world challenges exist and what tools we have that make the most sense to solve them, especially in balancing the deployment cost with the safety benefit to the community. At Synapse, we have a strong desire to develop products that ease our impact on the environment and protect people’s quality of life, and see a huge opportunity in the industrial space for smarter technologies to provide safety and cost-saving benefits. We’re constantly exploring ways to apply emerging technologies to existing industrial systems with safety in mind.

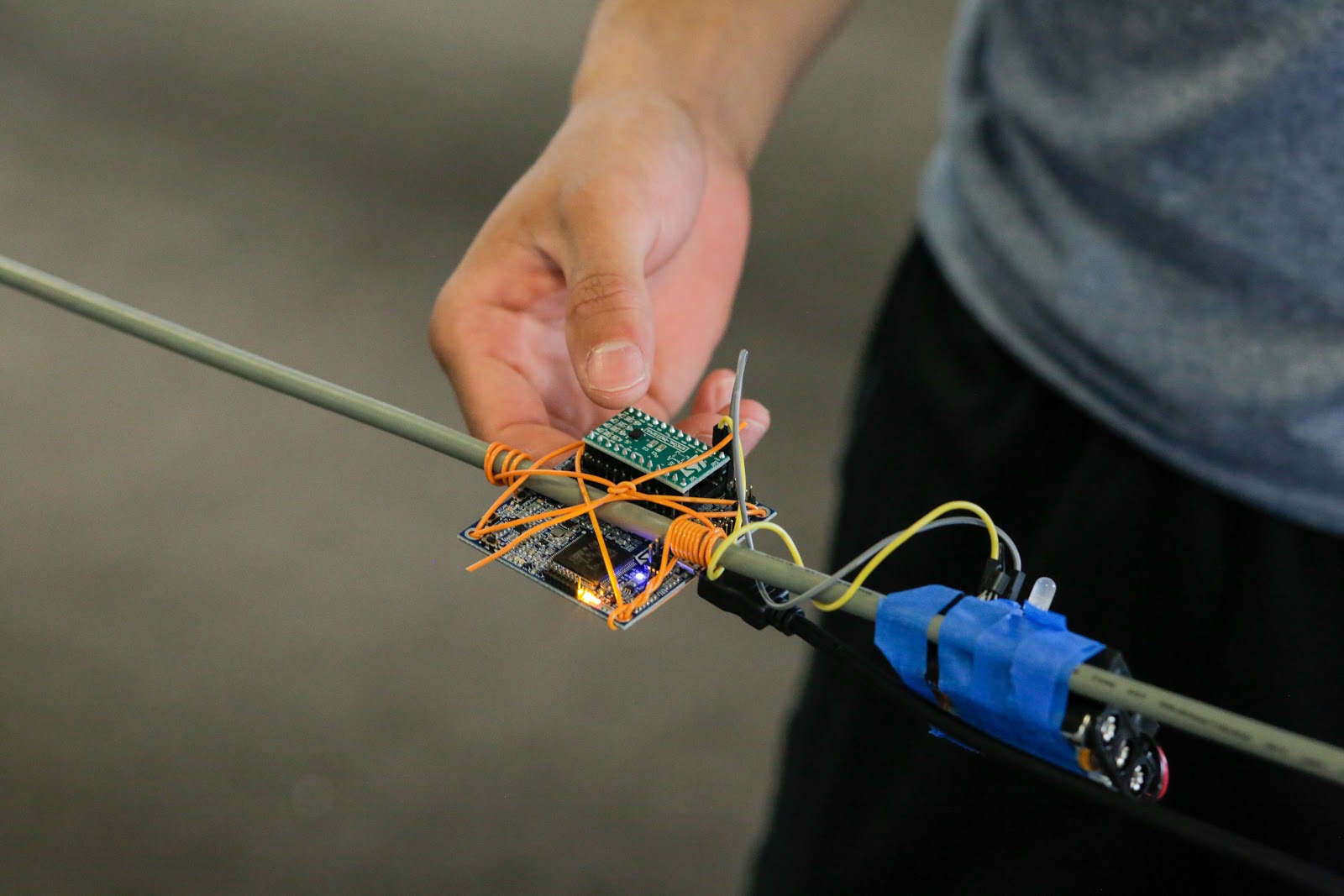

We have also invested our own time in proving out concepts that could be applied to power line monitoring and similar industrial-scale problems. Synapse has specifically identified the areas of edge-AI sensing, power harvesting, and secure mesh networks as potential focal points for addressing power line safety. Through talking with leaders, engineers, and regulators in the utility space, we are looking to further understand existing monitoring technologies and pain points. And as engineers, we are always looking to build and test ideas—most recently, working towards building a proof-of-concept demo for impact-sensing utilizing low-power edge AI technology.

Using our learnings in consumer embedded tech and other similar AI applications, we have been working to train a representative model of a power line with an attached sensor to recognize the signature of certain events such as wind and tree branch impacts. The learnings from this, and other small projects that focus on the technical focal points of smart sensing, will help us identify approaches and engineering tools that work well and may be able to help solve the technical challenges presented by power line monitoring.

Seeing the worsening conditions and increasingly common effects of fires on the West Coast firsthand has urged us to explore what we as engineers and innovators can do to help to tackle this complex and multi-faceted problem. The past week of suffocating wildfire smoke has been a dramatic reminder of the damage this season’s unprecedented fires have caused. Fighting wildfires will require work from everyone, from policy-makers to organizations to individuals, and the threat is not going away. Climate change research has shown an increasing trend in the number of days of high-risk fire conditions over a longer fire season, making it critical for us to limit our risky behaviors and infrastructure that contribute to fire ignitions. Our reliance on our electrical grid will only increase with investment in renewables and as we move away from fossil fuels, themselves a contributor to the climate crisis. We can only do so much to mature this technology through internal investments, and we’re calling on stakeholders in wildfire-affected regions to recognize the benefits of investing in smarter, connected power line monitoring systems to help fight this growing and persistent problem. If you’re ready to take action, we’re here to help.