What if there was one product design strategy that optimized every feedback loop for a circular economy?

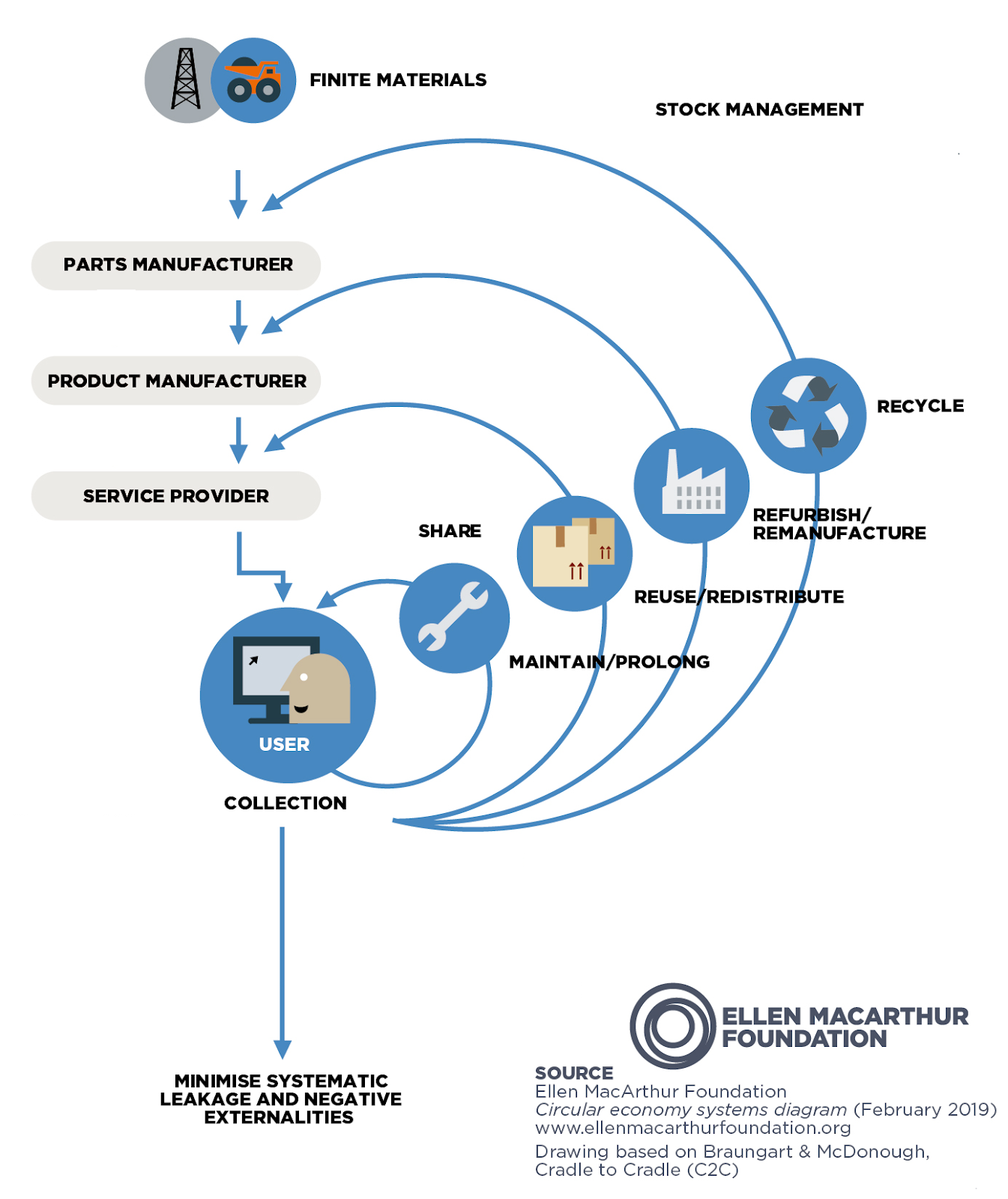

The Ellen MacArthur Foundation has defined several loops that are applicable to consumer products when considering a circular economy. These are seen in the infographic below:

- Repair/Maintain (Shown as Maintain/Prolong Below)

- Reuse/Redistribute

- Refurbish/Remanufacture

- Recycle

The size of each loop is representative of the additional energy and resource input required to complete, including any impact from packaging and transportation, so it is best to leverage the smallest loop possible. We’ll be exploring the advantage of modular design for each of these loops.

Designing for modularity is the most significant product development step that can be taken when working towards a circular economy. It contributes to greater availability of resources, diminishes waste generation, and reduces environmental impact within every feedback loop.

Loop #1: Repair/Maintain

Using a product for longer is the easiest and most substantial way to improve overall impact, and is referred to as life extension. The ‘Repair/Maintain’ loop is the smallest, as additional resource consumption and waste streams are significantly reduced. A defining factor for this loop is the ability of the consumer to accomplish any necessary steps on their own with minimal effort.

If the consumer is able to repair product wear or damage on a modular level, new purchases can be delayed or avoided entirely. Targeted and preventative maintenance or upgrades could be performed only on necessary portions of the product, extending the usable life and reducing additional resources.

Modular design inherently breaks the product into smaller pieces, which allows for isolated repair, replacement, or upgrade of sub-assemblies. Receiving only the modules of interest also minimizes the packaging and transport impact. When a product is designed for modularity, there is an opportunity to simultaneously design for repair. Considerations such as module accessibility, tools required for removal, and number of elements will influence the repairability of the product. Reclamation of replaced modules must be considered, or an additional waste stream has been created.

Empowering the consumer with the capability to replace worn or damaged pieces of their products allows them to be used for longer, extending the life of the product which results in significant improvement to environmental impact. The ‘Right to Repair’ movement is gaining momentum, fueled through channels such as Repair Cafes and online tutorials like IFIXIT. The ability of the consumer to do their own product repair is paramount for this feedback loop, and modular product design will make this more accessible and thus more likely to occur.

Loop #2: Reuse/Redistribute

The second smallest feedback loop is ‘Reuse/Redistribute’, which is typically facilitated by a service provider or the second-hand market. Products are either reclaimed and resold or are shared in a life-intensification business model (such as E-Bike rideshares). In either case, maintenance or repair will be performed by the service provider with the opportunity for customization or upgrade between uses. The goal of this loop is to reduce the number of products owned by consumers when use is intermittent or infrequent and otherwise keeping usable products in the market for as long as possible.

If a consumer only had possession of a product when they needed it, and there was an easy method for returning products when desired, fewer products could be manufactured, fewer products would be discarded and products that have already been created would be used for longer.

Similar to ‘Repair/Maintain’, modular design of a product will vastly improve the business viability of this feedback loop. Replacing only the necessary components in an efficient process with the opportunity to upgrade is the foundation of modular design. The impact from packaging and shipping is larger in this loop, as entire products are moved around.

Providing consumers with the option to purchase pre-owned products or only have a product in their possession during use can significantly reduce the number of products being manufactured, which limits resource use as well as waste streams.

Loop #3: Refurbish/Remanufacture

When a product has been damaged beyond user repair, is incomplete, or has otherwise lost its usefulness, value can still be retained in the ‘Refurbish/Remanufacture’ feedback loop. The distinguishing factor for refurbishing or remanufacturing versus repair is in the depth of the product structure being changed, generally requiring a manufacturing facility, with the product going to a new user.

If a product manufacturer could source used materials through product reclamation rather than relying on new parts, there would be a noteworthy reduction in new parts required in product manufacturing. Modularity in design would optimize the capability to sort, clean, repair, reconfigure and recombine portions of the design with high value. This reduces additional energy and resources and results in a cheaper product for the consumer.

When done correctly, modular design will break the product into functional blocks which have value beyond the original use case. This could be ease of ability to upgrade or compatibility within a broader product family. The intent is to make each portion of the product as inherently valuable as possible, even as the product ages and newer more attractive products become available. As the manufacturing facility may be far away from the product, the impact from shipping must be carefully considered and cost may become a barrier.

When repair or reuse is not practical or feasible, remanufacturing is the next best way to retain the value of a product. With modularity, the likelihood of value remaining in segments of the product is increased which will result in fewer new materials needed and less energy required for new products.

Loop #4: Recycle

The final feedback loop, ‘Recycle’, should only be considered when there is no longer any value in keeping components or modules intact. Recycling feeds back into part manufacturing and will provide an alternative source of raw materials.

Modular design will allow for the optimization of recycling methods for each portion of the design, rather than settling for one method for the entire product. In many cases, a product will have multiple materials, assemblies, and components assembled together which complicates the product level recycling process.

With modular design, disassembly to module level is inherently easier and results in an advantage when considering recycling methods. Generally, the product could be designed to break down into greater material homogeneity at the module level, and reduce the energy required for sorting and classifying. Safety is also improved through easy removal of batteries or other hazardous materials.

While ‘Recycling’ is the final feedback loop, it is still critical to consider because it is the step that actually feeds raw materials back into the circular economy cycle. The impact from refining new materials is avoided, and the waste stream is minimized. Designing for true end of life is still critical, as there will always be some waste. The safety of materials to humans and the environment must be factored into the decision process.

Overall Impact

If a product is designed for modularity with repair, reuse, remanufacture, and recycle loops in mind, there would be a significant improvement to larger availability of resources, a drastic reduction in waste generation, and a reduction in environmental impact in every step of the product life cycle.