Building the first major integrated prototype for a new product can be an exciting time for our clients. Often this Alpha prototype is the first opportunity for our clients’ revolutionary and ground-breaking products to feel real. The realities of every client’s business needs and the expectations of their stakeholders should inform the type of Alpha prototype that is best for this initial spin. Synapse has extensive experience in helping plan Alpha prototype strategies based on business needs. In this post, I’ll describe a couple of different Alpha prototype scenarios and discuss some of the downsides and highlights of each.

For some parts of this exercise, it will be helpful to have a specific product in mind. Let’s say the product in question is a wrist-worn device that monitors body temperature and alerts the user via a connected phone app if they are running a fever. Let’s take a look at what this would look like in the first scenario.

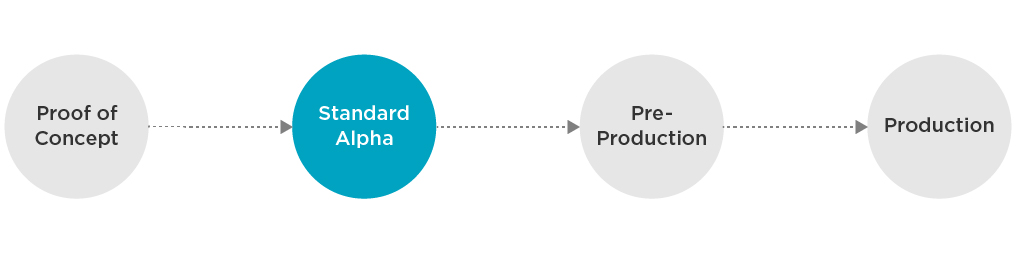

Scenario 1: The Standard Alpha Prototype

In Scenario 1, our client is a Fortune 100 company. The product has strong internal approval throughout the company and there is an intent to mass produce the product. This scenario is often representative of the “standard” product development cycle we see here at Synapse, which consists of a sequence of prototyping efforts designed to sequentially reduce overall product risk as the design is ramped to mass production. While sources may differ slightly on the terminology and number of stages, the standard product development cycle generally follows this approach:

The Proof of Concept prototype is just that; a single prototype that proves the concept of the primary technical challenges or risks associated with your product. This prototype often looks nothing like the final product. It may be a collection of development kits, lab-grade power supplies or controllers, and 3D printed parts. Oftentimes, an emphasis is placed on the ability to quickly analyze how various variables affect overall performance, so selecting highly modular off-the-shelf components can make this easy. In some instances, the Proof of Concept prototype may place a strong emphasis on validating a key user experience element. But, once the Proof of Concept prototype has done its job of demonstrating the feasibility of the technology and de-risking the major areas of risk, it’s time to move to the Alpha prototype—commonly the first fully integrated design.

It’s here at the Alpha prototype phase that we often see the major divergence in our two scenarios. For the standard development cycle, the Alpha prototype is the vehicle used to analyze and de-risk as many significant technical risks as feasible. Achieving the target form-factor and making the device look polished is not typically a goal of this prototype (unless achieving the target form-factor is the key technical risk). A near-form-factor design using non-production part fabrication processes is typically adequate to assess key technical risks for your device. For our device, the Alpha prototype could be a wrist-worn prototype that uses the production microprocessor, Bluetooth® radio and antenna, and a prototype version of the sensing FW. However, this prototype may be implemented in a CNC machined housing (rather than injection molded) and may use a PCBA that is 30% larger than the target design size to allow for more exposed headers and test-pads for easier electrical and RF analysis. Prioritizing fast learning is the key at this stage of development; whatever can be done in Alpha to make it easier for the engineering team to learn about the performance of the high-risk areas will give a big return on investment in later phases.

While this version of the Alpha prototype is critical in achieving success and reducing costs in later phases, it does have some downsides. The lack of polish on this prototype can often be a let-down to tangential stakeholders. Setting expectations with all stakeholders is critical before executing the Alpha prototype spin. The goal of this prototype is to learn and test the areas of the design that are highest risk. Needlessly accelerating cosmetics could easily be money poorly spent if major design issues are discovered that affect the size or shape of the product.

Sometimes, it can be critical to have an artifact that can generate the “wow” factor needed to keep a tangential stakeholder impressed and feeling that the project is on track. In this case, we often find that a cosmetic “beauty model” can be a low-cost prototype that can ride alongside your Alpha. A few thousand dollars spent on some very high-quality beauty models (typically 3D printed and painted) can be a worthwhile investment.

Taking the Alpha prototype approach outlined above perfectly positions our clients to move to the Pre-Production Phase. Once the major design and performance risks have been explored, shortfalls can be addressed in the Pre-Production build(s) which will have a goal of building the product in form-factor using the production processes. This is a big step in the maturity of the product, and I can’t stress enough the importance of laying a strong foundation in the Alpha phase.

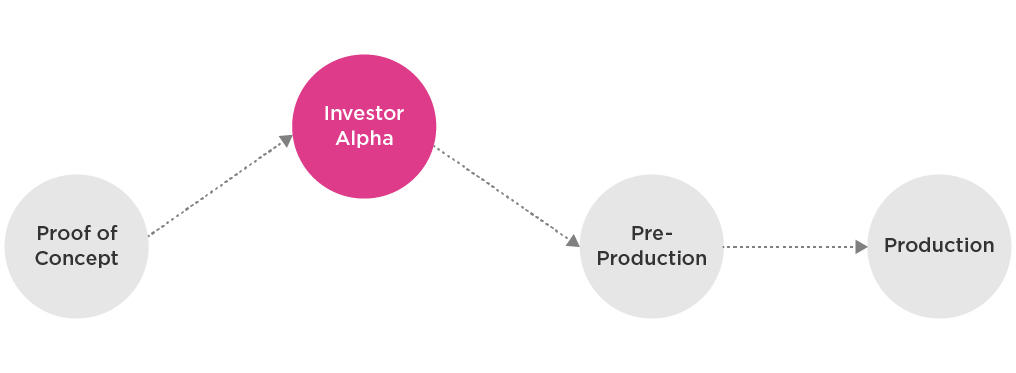

Scenario 2: The Investor Alpha Prototype

In Scenario 2, our client is a startup, and this is their first hardware development effort. They’ve secured enough funding to get through their first integrated prototype spin, but need to secure additional funding to keep the project going before marching towards mass production. Generating enough interest from investors to get the next big round of funding can be challenging. Demonstrating progress to the point that investors are willing to spend thousands or millions of dollars to continue funding development does often require the “wow” factor that we specifically avoided in Scenario 1. Alternatively, additional funding may specifically be tied to hitting a very specific performance requirement that is achievable in the long run, but may be a hard stretch at this early stage of development. Therefore, this prototype sits at the same spot in the overall design cycle, but with different goals.

It is certainly feasible to create a prototype that achieves one or even both of the goals of cosmetics and performance at this stage, but it comes with a major downside. Many times, this Investor Alpha can be a deviation from the main product development path without a clear path back to Pre-Production. To achieve impressive cosmetics without producing injection molded parts, parts may need to be machined and then painted or textured by hand to achieve the appearance of final components, which can often be very expensive. While the ubiquity of “prototype tooling” has enabled impressive cosmetics earlier in the project, this is typically only applicable on smaller devices with relatively low complexity parts. Additionally, meeting the form-factor requirements of the device at this stage may make it very difficult for the engineering team to analyze critical systems in prototype testing due to lack of physical access.

Similarly, when it comes to performance of the device, more expensive, more powerful, or more exotic components may need to be used inside the device to achieve the production-intent performance requirements, because the prototype components are simply not mature enough to do so. While this can demonstrate feasibility that the performance is achievable, it does so at the expense of learning about cost, power consumption, and component durability—all things that would normally be critical to assess in the Alpha phase.

While I have outlined several downsides of this approach, there is nothing inherently wrong with needing to take this approach to secure additional funding. This is simply a necessity of many of the world’s great new and innovative products.

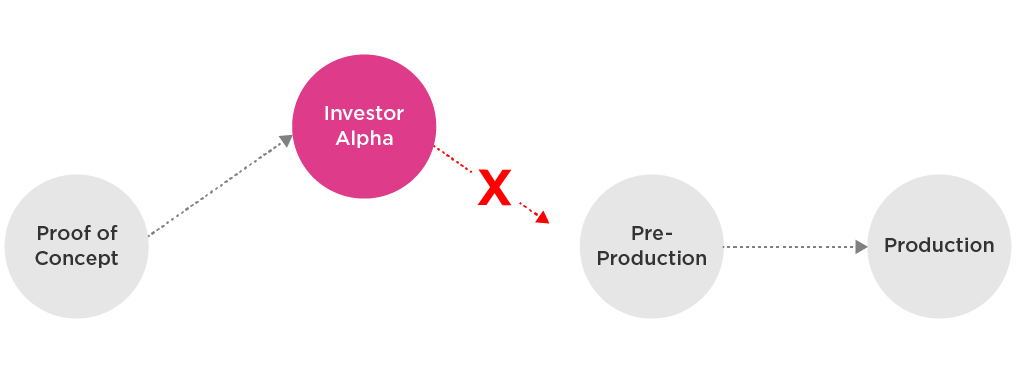

With funding secured from investors, the job of getting back to readying the product for mass production can move forward. However, here’s where the downsides described above manifest. In the graphic above, the Investor Alpha was offset from the main product development line. This is because it is often not sufficient as a stepping stone on the way to Pre-Production. Because such a heavy emphasis was placed on cosmetics and end performance (out of necessity!), critical risk areas are often not fully analyzed. Moving directly back to a Pre-Production prototype phase can often be a disaster. Realizing in Pre-Production that a key aspect of your solution doesn’t work because it was not fully analyzed in the Investor Alpha can lead to a huge amount of wasted money because there has already been such a significant investment in manufacturing and bringing a contract manufacturing partner online.

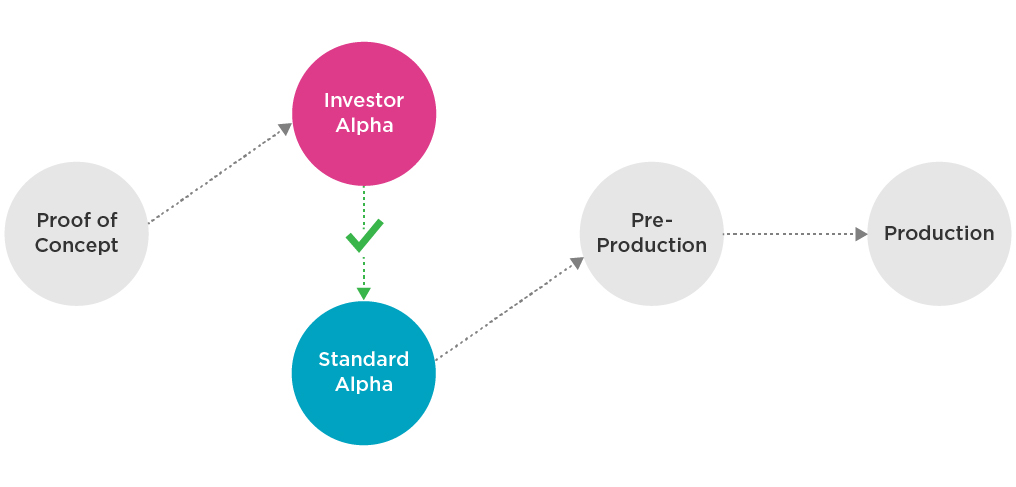

Instead, the safest approach is often to move back to a Standard Alpha. Though this can often feel like a step backwards, and be painful on the project budget at the time, doing this ensures more streamlined and successful Pre-Production prototyping cycles. Going backwards from Pre-Production to Alpha is much more painful and expensive than doing a second Alpha.

The good news is that even though the Investor Alpha may have eschewed critical analysis of all risk areas for its focus on cosmetics and performance, it typically has explored some areas of a Standard Alpha. Oftentimes a Standard Alpha that comes after the Investor Alpha can be abbreviated or focused on areas that were not explored in the Investor Alpha.

So What’s Best For You?

The choice of which path to pursue is often dictated by the reality of your funding situation and needs of your stakeholders, who will provide necessary financing or management approval of your Alpha prototype. Regardless of what is necessary, it’s critical to recognize the value and challenges of each to save money and time later on in development. You can focus on being smart and learning enough with your Alpha prototype to avoid technical setbacks or budget and schedule overruns in the future. Or you can focus on looking good to generate critical interest from investors. But it’s very hard to do both. As with anything in product development, understanding the needs of your stakeholders and carefully setting expectations with them is critical to success. Building the right prototype for your needs will build a strong foundation on the path to delivering a world-class product.