Additional contributions to this series made by: Ian Graves, Bret Richmond, & Mike Schaaf

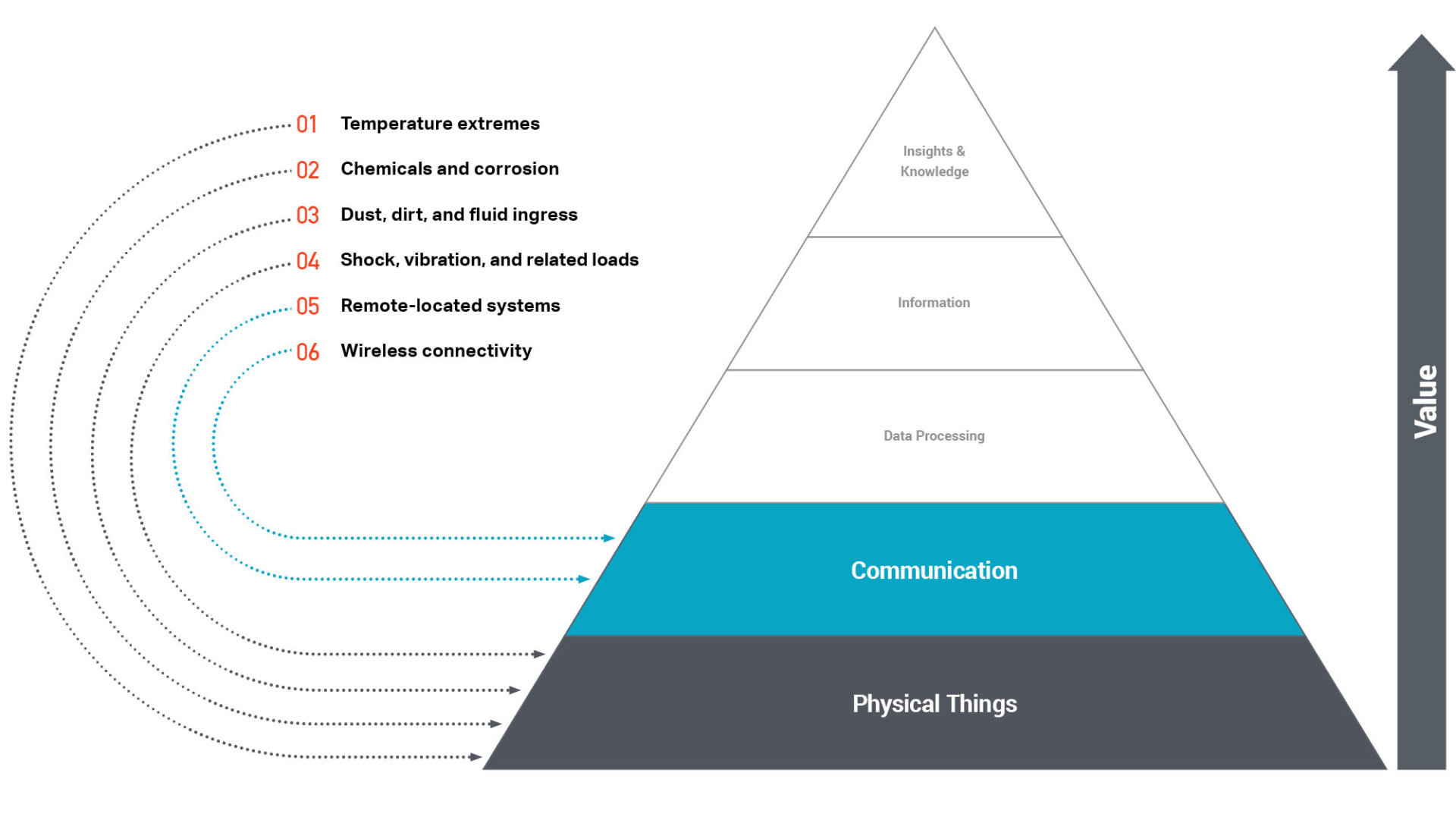

IoT devices operating in harsh environments are subject to a host of challenges associated with the potential lack of easy human access to the devices. An IoT monitoring device may be located in a highly remote area that is challenging to get to or may be located in an area of an industrial facility with temperatures or chemicals that render it inhospitable for humans.

PLANNING FOR–AND MITIGATING–POTENTIAL FAILURES IS EXTREMELY IMPORTANT FOR REMOTE DEVICES

Oftentimes, remote devices may need to be engineered for extremely low power consumption or the ability to deal with poor and inconsistent power quality. For example, an IoT device may be mounted on a remote cell tower and powered using a solar panel. In such a case, proper selection of electrical components, efficient firmware, or lower power wireless communication protocols maybe required to achieve a long field life under varying power conditions.

For products that cannot be accessed easily, a major design consideration is gracefully dealing with fault conditions if the products are unable to receive human intervention. At Synapse, we recognize that Failure Mode Effects Analysis(FMEA) is extremely important for these types of applications where high availability may be mission-critical. FMEAs conducted early indesign can ensure that proper redundancies, autonomous reset, or error correction is built into the hardware from day one.

ULTRA-LOW POWER SMART GAS METER

Today’s energy providers are constantly searching for ways to get better, more accurate consumption information. Quality data is important to provide accurate billing information for users and monitor the system to identify leaks and prevent theft. However, achieving this in this highly regulated market is difficult. Requirements for smart monitors are stringent; they must be connected through low power radio communications, have a long product life (approaching 30 years) and run off the same battery for up to 10 years.

For one of Europe’s largest engineering companies, they had to meet those requirements while updating their smart gas meter offering. A comprehensive hardware and software based approach was used, which relied on low power electronics and specialized data formulation to allow small amounts of power to transmit the correct information at the required intervals.

Leveraging this low power approach allowed the updated smart meter to be installed, calibrated and updated remotely throughout the region, ready for years of use.