To date, the majority of public investment and carbon dioxide removal (CDR) purchases, including $3.5 billion from the US government to establish Direct Air Capture (DAC) regional hubs, are in direct carbon capture. DAC is a closed system – the carbon being removed can be directly measured and the system has clear boundaries. For closed systems, measurement of carbon removed is straightforward and uncertainty is low. Getting to the necessary scale of CDR to limit global warming to 1.5 °C or 2 °C targets, however, requires investment in a diverse range of CDR technologies including those where quantification is more complex and uncertainty is higher.

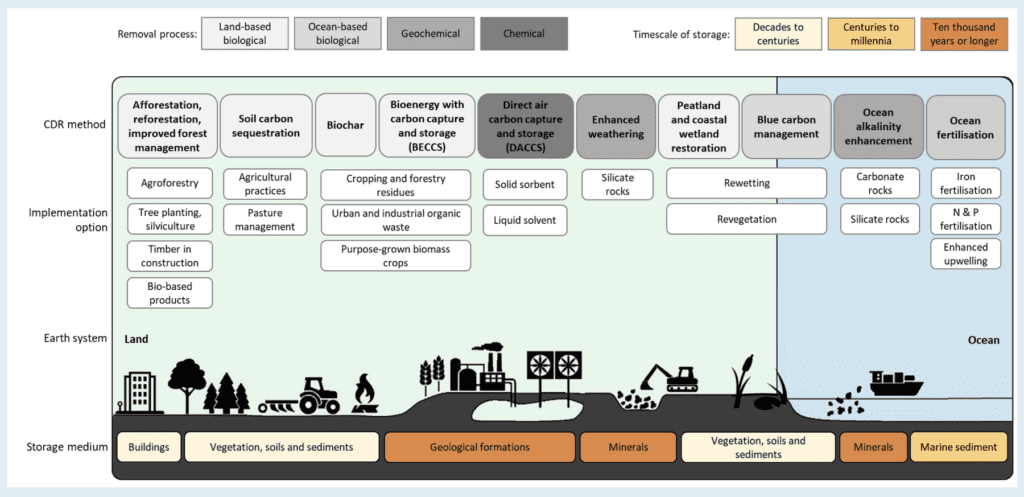

The graphic below from IPCC shows the range of different CDR technologies in active research and development. Note that the majority of these technologies are open systems where removal or storage processes are happening on a huge geographic scale without clear boundaries. These open system technologies require more sophisticated measurement and quantification tools than closed systems like DAC.

The link between uncertainty and CDR costs

Any CDR solution has an uncertainty range on how much carbon is being captured. For open systems, this uncertainty range can be quite large.

When selling carbon credits, companies can only sell the number of credits at the bottom of the uncertainty range. An increasing number of open system CDR solutions are coming to market as investors acknowledge that even with high uncertainty, they can still compare favorably with closed system solutions on cost per ton of CO2 removed, time to market, or ability and speed to scale.

Improving uncertainty with better measurement

Improving the tools to measure carbon capture in open systems can increase investor confidence and funding in more of the technologies needed to scale CDR and bring costs down. The CDR market is currently in the process of defining better standards for monitoring, reporting, and verification (MRV) to enable better comparison and promote investment and development across a variety of CDR pathways.

The measurement aspect of MRV has a direct and straightforward impact on costs of open system CDR technologies at scale. Better sensor solutions can allow companies to capture more value through reducing uncertainty on the amount of carbon removed. As part of MRV, system models are already in place to predict how much carbon is captured and the uncertainty range. Sensor solutions can be added to the model and we can get a prediction for how much uncertainty would be reduced with sensor solutions and the corresponding cost of the additional carbon removal credits. Sensors can also be used to validate and improve the complex models used in open system MRV. Some sensors are available off the shelf, some need to be adapted to a new environment, and some situations require custom sensor development. The costs of even custom sensor development may be justified by the additional carbon credits that can be sold, especially as industries scale to large quantities of carbon removed.

Improved MRV and CDR costs — an example

As a concrete example of how this could work, let’s build upon the excellent case study from Frontier on their approach to quantifying carbon removal. They present a cost comparison of Enhanced Rock Weathering (ERW), an open system with higher uncertainty, to Direct Air Capture (DAC), a closed system with low uncertainty. The chart below is reproduced from their blog post. The cost per ton of ERW is substantially lower than with DAC, even with a significantly higher cost for MRV.

| DAC | ERW | |

| CDR cost per ton (with MRV) | $800 | $250 |

| MRV cost per ton | $20 | $40 |

| Uncertainty discount | 5% | 34% |

| Cost per ton delivered | $842 | $379 |

| MRV cost per ton delivered | $21 | $61 |

To explore how sensor solutions can impact CDR cost per ton delivered, let’s build on this example. Per the Frontier case study, which we are using as a baseline, the major sources of uncertainty in ERW are alkalinity runoff, which is estimated by modeling and sampling, and leakage, which is modeled with data from literature. Imagine that we are exploring sensor solutions and have identified two potential sensing solutions that significantly reduce uncertainty when added to the MRV model.

For this example, let’s say that one option is a higher cost and more accurate method of sensing and the other is a lower cost but less accurate sensor – a tradeoff that we see frequently with sensor systems. As you can see, a more expensive sensor that decreases uncertainty to 20% but increases MRV costs by $30 is approximately equivalent in cost per ton delivered to a lower cost sensor that only decreases uncertainty to 25% but increases MRV costs by $15 a ton.

| ERW – baseline | ERW + precision sensor | ERW – low cost sensor | |

| CDR cost per ton (with MRV) | $250 | $280 | $260 |

| MRV cost per ton | $40 | $70 | $55 |

| Uncertainty discount | 34% | 20% | 25% |

| Cost per ton delivered | $379 | $350 | $347 |

| MRV cost per ton delivered | $61 | $88 | $73 |

Note that these are not real cost projections, just examples of how investments in sensing technology can pay off. In reality, companies might choose to pursue a strategy of large scale trials for both types of sensors to allow them to refine their models and decrease uncertainty and sensing costs over time and at scale. Sensor needs at prototype scale versus when a CDR technology reaches maturity will be different, and taking quality measurement data at prototype scales will allow companies to refine and improve models. This also doesn’t account for potential cost savings in MRV from reduced maintenance and service if we can improve sensor reliability, durability, and autonomy.

We can see the tradeoff between high cost, high accuracy and lower cost sensing playing out in the ERW space right now — the Carbon Drawdown Initiative recently released a paper describing their experiments with a low cost in field soil gas CO2 sensor. They compare this to LithosCarbon’s method of taking samples from a field and sending them to a laboratory to do an elemental isotope mass-balance analysis.

The laboratory analysis is extremely valuable for building and validating models during early field trials and can produce highly accurate data but there’s a practical limit to the geographical scale and time frequency that data can be measured at. The CO2 soil gas sensors can be built at scale and sample continuously but at a tradeoff of lower accuracy and technical challenges like sensor calibration and drift to overcome.

The future of sensing in MRV

Investment in better sensor systems — both the sensors themselves and the hardware, firmware and cloud platforms that enable cost effective data collection, transmission, storage, and integration with MRV models at scale — can accelerate the development and commercialization of the open system CDR technologies that the world needs to address the climate crisis.

At scale, large numbers of sensors will be needed and sensor and platform development needs to happen in parallel with the rest of the infrastructure for CDR to be sufficiently mature and ready to build in quantity as CDR scales.